Table of Contents

Even the most advanced LED displays, known for their reliability and high performance, can encounter issues over time. Despite their durable design, problems like signal loss, pixel failures, or color inconsistencies can arise.

However, most of the LED display problems can be fixed quickly and can even be avoided with some proactive measures. This article focuses on the most common LED display problems that you can face, while also providing clear, practical solutions.

LED Display Problems and Solutions: Troubleshooting Guide

1. Black / Completely Dark Screen

Symptom: The entire display is dark (no image).

Cause:

- Power failure: No AC input, blown fuse, or failed power supply.

- Faulty signal: Disconnected or damaged data cables (network cables between sending and receiving cards).

- Control system issue: Sending card failure, or misconfigured sending-card settings/software.

- Software configuration: Wrong screen resolution, wrong scan mode, brightness set to 0, or control software crashed.

Solution:

- Check power—Verify AC input, check whether power supply modules are working, fuses, breakers, etc.

- Inspect data cables—Reseat network/data cables between sending card and receiving cards.

- Test control card—Check the sending card indicator LEDs; if faulty, swap in a known-good card.

- Verify software settings—Open your control software and check brightness, resolution, and scan mode. Reload the correct configuration profile if needed.

- Use alternate input—Connect backup media player or PC to see if the source is the issue.

2. Intermittent Signal Loss or Flashing

Symptom: The screen flickers, blanks out, or flashes intermittently.

Cause:

- Loose or poor power connections (power cord not tightened or degraded).

- Power supply overload or instability.

- Poor network/data cable connection (e.g., between sender and receiver).

- Software miscommunication: Corrupted configuration, bad firmware, or dropped data packets.

Solution:

- Secure power lines—Tighten power connectors, ensure no damage, and verify load on the power supply.

- Upgrade or distribute power—If the PSU is overloaded, replace it or add redundant power supplies.

- Check data cables—Reseat and inspect the network/data cables carefully; replace if worn or damaged.

- Reflash or update firmware/software—Refresh sending-card firmware, re-upload config, or restore from a backup profile.

3. Dead or Stuck Pixels

Symptom: Individual pixels (or small clusters) remain dark (dead) or fixed on a color (“stuck”).

Cause:

- Faulty LED lamps, solder failures, or LED-bead damage.

- Data line issues: Poor connection between module and receiving card.

- Driver IC failure on the module.

Solution:

- Run pixel-mapping software—Identify which modules or pixels are problematic.

- Inspect and test modules—Swap in a known good module, or open and inspect driver ICs, solder joints, and data lines.

- Replace modules or IC chips—If the faulty LEDs or driver ICs are identified, replace them.

- Preventive maintenance—Regular checkups and module testing can catch pixel issues early.

4. Uneven Brightness or Color Inconsistency

Symptom: Some areas of the display look brighter or dimmer than others; colors don’t match across the screen.

Cause:

- Aging LEDs or driver IC drift, which changes brightness over time.

- Uneven voltage distribution or power supply problems.

- Poor color calibration, or modules from different production batches.

- Environmental factors (e.g., heat, moisture) causing differential degradation.

Solution:

- Color calibration—Use professional tools (e.g., spectroradiometer) and softwareto recalibrate brightness and color.

- Check and balance power—Use a multimeter to verify each module’s power supply voltage is within specification.

- Replace mismatched modules—If modules are from different batches or some have aged more, swap them for more uniform ones.

- Improve environmental protection—Ensure cabinets are well ventilated, and protect against moisture to reduce degradation.

5. Lines or Bars Across the Screen

Symptom: Horizontal or vertical lines/bars, color bands, or “stripes” appear.

Cause:

- Bad or oxidized ribbon/data cables between modules.

- Faulty driver ICs on modules causing some rows or columns to misbehave.

- Moisture or corrosion on connector points (especially outdoors).

Solution:

- Inspect and replace cables—Check ribbon/data cables for wear; replace HUB75 or flat cables if needed.

- Use a hot-air gun repair trick—For some driver-IC strip issues, carefully heating the area can reflow solder on ICs.

- Replace faulty ICs—Identify and swap out bad driver ICs (e.g., TD62783 or others as per module spec).

- Moisture protection—Apply dielectric grease to connector points, ensure cabinet sealing, and improve drainage/ventilation.

6. Display Is “Scrambled,” Fragmented, or Shows Duplicated Content

Symptom: The image appears fragmented or torn, or the content is duplicated in patches.

Cause:

- Signal synchronization error: Control card misconfiguration, wrong mapping of receiving cards.

- Data transmission issues: Packet loss, corrupted cables, or a bad sending card.

- Software misalignment: Incorrect layout configuration in control software.

Solution:

- Check and remap receiving card addresses—Make sure each receiving card is correctly assigned in the control software.

- Verify signal integrity—Inspect and replace any suspect data cables, check the sending card, and ensure firmware is up to date.

- Reload configuration—In your control software, re-upload or re-configure your profile to match the exact panel layout.

- Use diagnostic tools—Many LED control systems have built-in diagnostics for signal continuity and card health—use them to isolate the issue.

7. Ghosting or Image Retention

Symptom: After moving images, you still see faint “ghost” traces, or static content leaves a residual shadow.

Cause:

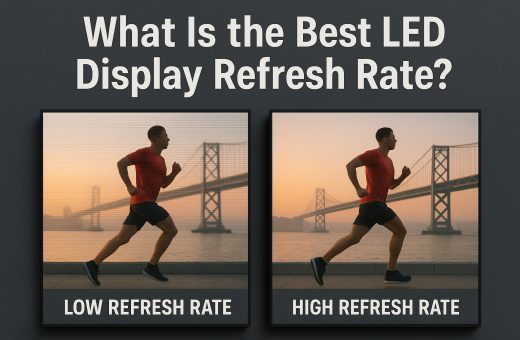

- Low refresh rate or improper PWM settings, which don’t fully refresh pixel states.

- Poor quality or long data cables causing delayed or smeared signal.

- Aging driver ICs or LEDs that don’t respond cleanly to new frames.

Solution:

- Increase refresh rate / adjust PWM—In your control system, raise the refresh rate and fine-tune PWM to reduce ghosting.

- Use high-quality data cables—Use well-shielded, short cables to minimize signal degradation.

- Replace aging modules or ICs—If certain modules are slow to respond, replacing driver ICs or modules may be needed.

- Regular calibration—Periodically calibrate the display (color, brightness) to ensure signal consistency and avoid residual artifacts.

Proactive Maintenance and When to Call an Expert

1. Proactive Maintenance (Preventive Tips)

- Regular Cleaning: Power off the display and gently clean the surface with a soft, lint-free cloth or a specialized LED screen cleaner.

- Periodic Calibration: Use your control software to perform brightness and color calibration checks every few

- System Checks: Routinely check the control system software for updates, verify cable connections are secure and corrosion-free, and monitor the operating temperature and humidity within the cabinet to prevent environmental stress.

2. When to Call a Professional?

Call an authorized technician or expert immediately for LED screen issues beyond basic troubleshooting:

- Persistent Electrical Faults: Repeated power failures, overheating, humming, or burning smells. Unsafe electrical/grounding conditions.

- Moisture or Water Ingress: Water has entered the cabinet, requiring specialized drying and repair to prevent short circuits.

- Major Component Failures: Need to replace thepower supply, LED module (dead/failing), or control card (sender/receiver).

- Complex System Issues: Calibration or color uniformity problems that you can’t resolve, or complex/recurring signal/firmware issues.

- Safety/Access Concerns: The display is high or hard to reach, making DIY maintenance dangerous or impractical, or repair would void the warranty.

- Annual/Periodic Inspection: Set up a service contract for large, mission-critical displays to catch latent issues.

Chainzone’s Approach to Better LED and Better Control

Chainzone delivers a connected and intelligent approach to LED display management through our Integrated Management Platform (IMP). This cloud-based system lets users monitor, control, and maintain multiple displays remotely, combining hardware and software management for smooth operation and real-time oversight across networks.

IMP offers real-time monitoring that detects pixel-level faults instantly and issues automatic alerts to minimize downtime. It also supports multi-device access, enabling teams to manage content and hardware from computers, mobile devices, or web browsers through one unified interface. This integration simplifies scheduling, configuration, and visual updates without switching systems.

For maintenance, Chainzone provides a suite of tools that streamline field operations. For instance, ChainMaster acts as the central control hub, ChainGo enables on-site task management, and Mager Pro handles advanced diagnostics and remote support.

Together, these tools create an efficient workflow that improves coordination, accelerates LED screen problem troubleshooting, and reduces downtime.

Wrapping Up

As powerful communication tools, LED displays require dependable technology and smart management to detect any LED display problem quickly and address it efficiently.

Chainzone continues to stand out by offering advanced, energy-efficient LED solutions supported by its Integrated Management Platform. With innovation and dependability at its core, we help businesses achieve brighter displays, smoother operations, and long-term value!